Aluminium Alloy Ingots

Aluminium alloy ingots are the initial forms of aluminium alloys produced through the casting process. The process involves melting a specific combination of aluminium and alloying elements and then cooling the molten metal to solidify it into ingots. These ingots serve as raw material for further processing and manufacturing of various aluminium products.

Aluminium alloy ingots are typically identified by their alloy composition, which determines their properties and applications. Different alloys are designed for specific purposes, such as improved strength, corrosion resistance, or suitability for casting processes.

The ingots can be further processed through methods like extrusion, forging, rolling, or casting to create a wide range of aluminium products, including sheets, plates, bars, and intricate components for diverse industries such as aerospace, automotive, construction, and more.

The choice of a particular aluminium alloy and its ingot form depends on the intended application and the desired characteristics of the final product.

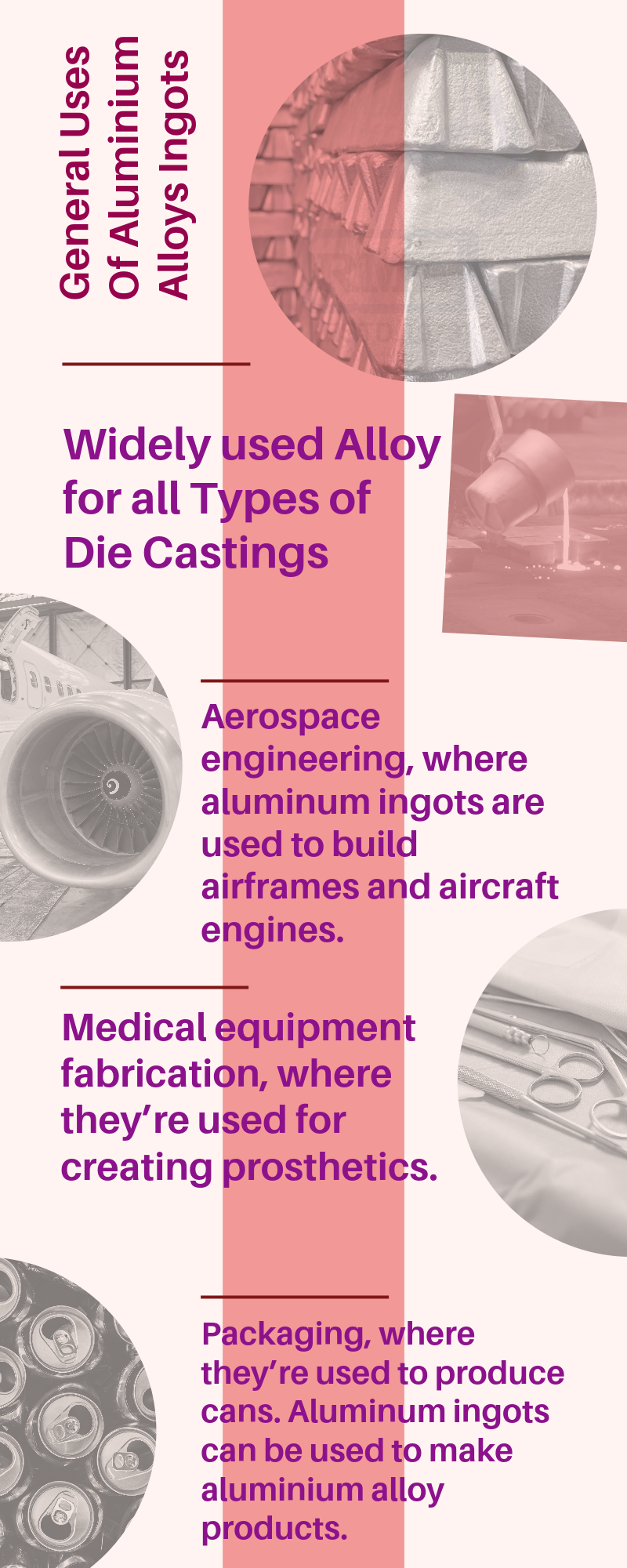

General uses of aluminium alloy ingots

Aluminium alloy ingots are very useful in various applications like casting of many aluminium products. These are used in die castings, used in aerospace engineering, used in medical equipment fabrication and also used in packaging industry.

lm6 aluminium alloy composition

LM6 is a popular aluminium alloy known for its good castability and high strength. The composition of LM6 alloy typically includes:

Element Name | % Composition |

Silicon (Si) | 10.5-13.0% |

Copper (Cu) | 0.2-1.0% |

0.2-0.6% | |

Iron (Fe) | 0.6% max |

Manganese (Mn) | 0.5% max |

Nickel (Ni) | 0.2% max |

Zinc (Zn) | 0.1% max |

Titanium (Ti) | 0.2% max |

Others (each) | 0.05% max |

Others (total) | 0.15% max |

Aluminium (Al) | Balance |

These alloying elements contribute to the overall properties of the alloy, such as strength, corrosion resistance, and heat resistance. The specific composition may vary slightly depending on the manufacturer or specific application requirements.

6063 aluminium alloy

6063 aluminium alloy is another very good and useful aluminium alloy. The composition of the 6063-aluminium alloy is as follows:

Element Name | % Composition |

Silicon (Si) | 0.20-0.60% |

Iron (Fe) | 0.35% max |

Copper (Cu) | 0.10% max |

Manganese (Mn) | 0.10% max |

Magnesium (Mg) | 0.45-0.90% |

Chromium (Cr) | 0.10% max |

Zinc (Zn) | 0.10% max |

Titanium (Ti) | 0.10% max |

Others (each) | 0.05% max |

Others (total) | 0.15% max |

Aluminium (Al) | Balance |

6063 is commonly used for extrusion applications and has good corrosion resistance and weldability. The alloy is often used in architectural and structural applications due to its favourable combination of strength, formability, and surface finish.

%20(1).png)