Metals and Non-Metals

Metals

Metals are the solid materials

which are typically hard, malleable, ductile and conduct heat and electricity,

and also possess metallic lusture.

Example- Iron, Gold,

Aluminium, Silver, Copper etc.

Nonmetals are chemical

elements which lacks metallic properties. Non metals are either solids or gases

except Bromine (Br2), which occurs as liquid. Non-metals vaporizes

easily, insulator of heat and electricity. Nonmetals have high ionization

energy and electronegativity values.

Example- Hydrogen, Helium,

Nitrogen, O2, F2, Ne, Cl, Ar, Kr, Xe, Rn, Br, C, P, S,

Se, I.

Exception in metals and non-metals

·

Mercury is liquid

at room temperature while other metals are solid.

·

Gallium and caesium

have very low M.P. while other metals have very high M.P.

·

Iodine is

non-metal but it has lustre (shiny).

·

Carbon

(Non-Metal) exist in different forms, and these forms are known as allotrope.

·

Graphite

(allotrope of carbon) conduct electricity and Diamond (allotrope of carbon)

having very high M.P. and B.P. is hardest natural substance known.

Chemical properties of metal

Burning of metals in air

Metals

burn in air (as oxygen present in air) to produce metal oxide.

Metal + Oxygen -------> Metal Oxide

Example- 2Cu (Copper) + O2

(air) ----> 2CuO (Copper Oxide)

4Al (Aluminium) + 3O2

--------> 2Al2O3

(Aluminium Oxide)

·

Mostly metal

oxide is basic in nature, but some metal oxides are amphoteric in nature i.e.

they show acidic as well as basic behaviour like Aluminium Oxide, Zinc Oxide.

Al2O3

+ 6HCl --------> 2AlCl3 + 3H2O

Al2O3 + 2NaOH -----> 2NaAlO2 (Sodium Aluminate) + H2O

·

Mostly metal

oxide does not dissolve in water but some dissolve to form alkali.

Na2O

(s) + H2O (l) ----------> 2NaOH (aq)

K2O

(s) + H2O (l) ---------> 2KOH (aq)

·

Some metals prevent

further corrosion by making protective oxide layer on itself like Al, Zn, Pb

etc.

·

Some metals like

Na, K catches accidental fire so to prevent it, they are kept fully immersed in

kerosene oil.

Reaction of metals with water

Most metal react with water to form metal oxide and hydrogen gas.

Metal + Water ------> Metal Oxide + Hydrogen Gas

2K (s) + H2O (l)

--------> K2O (s) +

H2 (g)

Not all, but some metal oxide

reacts further with water to give metal hydroxide.

K2O (s) + H2O

(l) ------> 2KOH (aq)

Some metals do not react with

water like copper, lead, silver and gold.

Reaction of metals with acids

Most metal react with acids to produce salt and hydrogen gas.

Metal + Diluted Acid ---------> Salt + Hydrogen Gas

2Al + 6HCl (dil.) ----------> 2AlCl3 + 3H2

·

As HNO3

is strong oxidizing agent so, hydrogen gas does not evolve when reaction take place

between metal and nitric acid Because HNO3 reduces itself to

nitrogen oxides (N2O, NO, and NO2).

·

Aqua-Regia (Royal

Water) is freshly prepared mixture of concentrated Hydrochloric Acid (Conc.

HCl) and concentrated Nitric Acid (Conc. HNO3) in the ratio of 3:1.

Aqua

Regia have great dissolving power, highly corrosive, fuming liquids. Aqua Regia

have ability to dissolve gold and platinum.

Reaction of metals with solution of other metal salts

More reactive metal has ability to displace less reactive metal from

their compounds in molten or solution form.

For example, if metal A is

more reactive then metal B then it displaces metal B from solution of metal B.

Metal A + Salt Solution of B

------> Salt Solution of A +

Metal B

Fe (s) + CuSO4 (aq)

-----> FeSO4 (aq)

+ Cu (s)

Reactivity Series of Metals

Reactivity series is the series in

which metals are arranged as per order of decreasing activity. This reactivity

series is developed after performing so many displacement experiments. This series

is also called as activity series.

K

|

Pottasium

|

More Reactive

Reactivity

Decreases

when we move Top to Bottom Least Reactive |

Na

|

Sodium

|

|

Ca

|

Calcium

|

|

Mg

|

||

Al

|

Aluminium

|

|

Zn

|

Zinc

|

|

Fe

|

Iron

|

|

Pb

|

Lead

|

|

H

|

||

Cu

|

Copper

|

|

Hg

|

Mercury

|

|

Ag

|

Silver

|

|

Au

|

gold

|

How Metals react with Non-metals

As

we know every element has tendency to achieve completely filled valence shell

to get electronic configuration of nearby noble gas, for example a metal says

sodium (Na) react with non-metal chlorine (Cl) to get complete valence shell

so Na loose one electron from its outermost shell which is taken-up by chlorine

(Cl), as a result they both have completely filled valence shell. In this

process sodium become +vely charged and chlorine –vely charged and these charges

attract each other to form NaCl.

Na (2,8,1) --------> Na+ (2,8) + e-

Where,

Na+ is sodium cation

Cl (2,8,7) + e- ----------> Cl-

Where,

Cl-

is chlorine anion

Formation of Sodium Chloride

Na+ + Cl- -----------> NaCl

Properties of Ionic Compounds

Ionic

Compounds also called Electrovalent Compounds and their properties are

described below-

1. Physical Nature of Ionic Compounds

Ionic compounds are solid and hard due to strong force

of attraction between +ve and –ve ions. Ionic compounds are also brittle.

2. Melting and Boiling Points of Ionic Compounds

Ionic Compounds have high M.P. and B.P. as large

amount of energy is needed to breakup ionic bonds.

3. Solubility of Ionic Compounds

Ionic compounds are soluble in polar solvents like

water and insoluble in non-polar solvents like ether, kerosene etc.

4. Electric Conductivity of Ionic Compounds

Occurrence of Metals

Maximum

metals occur in earth’s crust and some metal occur in sea water. Metals and its

compounds exist as minerals and if the percentages of metals in minerals are

large then they are known as ores.

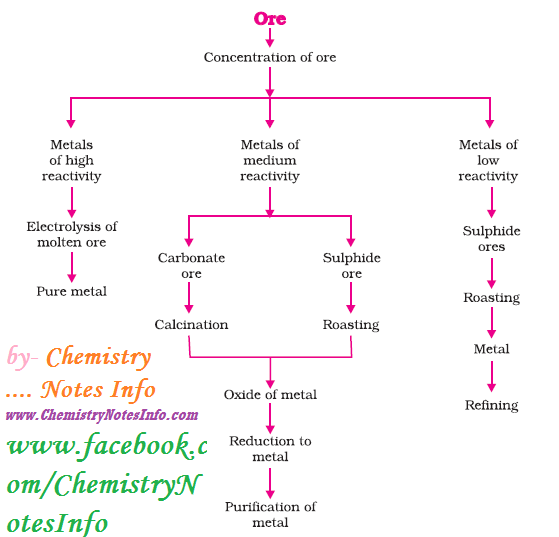

1. Extraction of Metals

Reactivity series is very helpful in

metal extraction as metals present at the bottom of reactivity series are least

reactive so found in Free State like gold, silver and platinum found in Free-State.

Metal at top is most reactive and metals in the middle are also reactive so

found in combined form. Metals generally found as oxides, sulphides and

carbonates on earth’s crust.

Steps involved in extraction of metals from ores-

2. Enrichment of Ore

The process

of removal of impurities or gangue from ore, before extraction of metal is

known as enrichment of ore.

Gangue is terminology used for impurities like sand,

soil etc. present in ore.

3. Extracting Metals Low in Reactivity Series (or Activity Series)

Metals present at bottom (or low

position) in activity series are very unreactive and can be obtained in pure

metallic form by just heating alone.

Example- Cinnabar (HgS), ore of Mercury (Hg)

2HgS (s) + 3O2 (g) + heat ----------> 2HgO (s) + 2SO2 (g)

2HgO (s) + Heat ------------> 2Hg (l) + O2 (g)

Similarly,

Cu2S, ore of copper (Cu)

2Cu2S + 3O2 (g)

+ Heat ----------> 2Cu2O (s) + 2SO2 (g)

2Cu2O + Cu2S + Heat ----------> 6Cu (s) + SO2 (g)

4. Extracting Metals in Middle of Activity Series

Metals in

middle like iron, zinc, lead etc. are moderately reactive and present as

sulphides or carbonates. Metals can be easily extracted from its oxides so

sulphides and carbonates are reduced to oxides. Then these metal oxides are

reduced to corresponding metal by using suitable reducing agent like carbon. Chemistry Notes by Chemistry Notes Info.

Roasting

It

is a process of converting sulphide ores into oxides by heating strongly in the

presence of excess air.

2ZnS (s) + 3O2 (g) + Heat

---------> 2ZnO (s) + 2SO2

(g)

Calcination

It is a process of converting carbonates

ores into oxides by heating strongly in the presence of limited air.

ZnCO3 (s) + Heat ----------> ZnO (s) +CO2 (g)

Oxide Reduction

Oxides of ores are reduced to metal by

using suitable reducing agent like carbon (Coke), or highly reactive metals.

ZnO (s) + C (s) ---------> Zn (s) + CO (s)

3MnO2 (s) + Al (s) -----------> 3Mn (l) + Al2O3 (s) + Heat

5. Extracting Metals at Top of Activity Series

Metals present at top in

activity series are very reactive and they are not obtained by heating their

compounds with carbon, for example Sodium, Calcium, Magnesium, Aluminium etc.

cannot be obtained by reducing with carbon as these metals have more affinity

for oxygen than carbon. So these metals are obtained by electrolytic reduction.

In

electrolytic reduction, the metals get deposited at cathode (-ve electrode) and

gas like chlorine get liberated at anode (+ve electrode)

Reaction for molten Sodium Chloride-

At Cathode :-

Na+ + e- --------> Na

At Anode :-

2Cl- -------> Cl2 + 2e-

Refining of Metals

Refining of metals are done to obtain

metals in very pure form by removing impurities present in it. Electrolytic

refining is widely used method for this purpose.

Electrolytic Refining

Electrolytic

refining is the method of obtaining very pure metals from impure metal. Metals

like copper, zinc, nickel, silver, tin, gold etc. are refined electrolytically.

In electrolytic refining, anode (+ve) is made from

impure metal and cathode (-ve) is made from thin strip of pure metal. Metal

salt solution works as an electrolyte. When we applied electric current across

the electrodes then current starts flow through electrolytic solution. Pure

metal comes out from anode and dissolve in electrolyte and equivalent amount

(i.e. to that comes from anode) of this pure metal from electrolyte solution

get deposited on cathode.

“In simple way we can say that pure metal come from

anode and get deposited on cathode by using electrolyte solution and electric

current.”

Insoluble impurities settle down below anode at bottom

and we say it as anode mud, while soluble impurities mix in electrolyte.

Corrosion

Natural

process of conversion of refined metal to its high stable form like oxides or

hydroxides of metals is known as corrosion. Corrosion is the process of gradual

destruction of any material like metals by environment and chemical reaction.

Example - Rusting of Iron

Prevention of Corrosion

There

are so many methods to prevent corrosion like-

1. Applied Coating

Applied

coating is surface treatment method. Planting, enamel application and painting

are applied coating method to prevent corrosion. These methods create barrier

between metal and environment.

2. Anodization

It

is anode surface treatment process in which we made thicker oxide layer at

metal surface.

3. Galvanization

Galvanization

is the process of coating steel and iron with very thin layer of zinc to

protect them from rusting.

Overall painting, greasing, oiling, chrome plating,

galvanizing, alloy making and anodizing are some ways for the prevention of

corrosion.

%20(1).png)